CONTENTS

2......... PURPOSE OF THE PLAN.. 1

3......... WASTE MANAGEMENT POLICY

AND STRATEGIES.. 2

4......... LEGISLATION AND

GUIDELINES.. 2

5......... LICENCE OR PERMIT

REQUIREMENTS.. 4

5.1

Registration as a Chemical Waste Producer 4

5.2

Dumping licence to Public Filling Area. 4

5.3

Dumping permit for Marine Disposal of Excavated Mud/Sediment 4

5.4

Registration as a Waste Producer under the Construction Waste

Disposal Charging Scheme 5

6......... PROJECT

ORGANISATION.. 5

7......... INDIVIDUAL DUTIES AND

RESPONSIBILITIES.. 5

7.6

Environmental Officer (EO) / Engineer (EE) 6

7.7

Environmental Supervisor 7

7.8

Environmental Team (ET) /

Environmental Team Leader (ETL) 7

7.9

Subcontractors and other Employees. 7

8......... WASTE CLASSIFICATION AND

CONTROL MEASURES.. 7

8.1

Construction and Demolition (C&D) Materials. 8

9......... WASTE MONITORING AND

AUDITING.. 12

9.3

Record Keeping and Reporting. 15

11....... MITIGATION MEASURES IN

EIA.. 17

12....... MITIGATION MEASURES IN

EM&A Manual 17

APPENDICES

Appendix A

Gammon’s Health, Safety and

Environmental Policy

Appendix B

Organisation Structure for Environnemental

Management

Appendix C

Contact List

Appendix

D

Proforma of Yearly Summary Waste Flow

Table

Appendix

Appendix

F

Disposal Scenarios and Transportation Modes

Appendix

G

Proposed

Temporary Storage and Sorting Area for C&D

Materials

Appendix

H

Memo from Marine Fill Committee of CEDD

Appendix I

Control Procedures on Off-Site Disposal of C&D

Materials

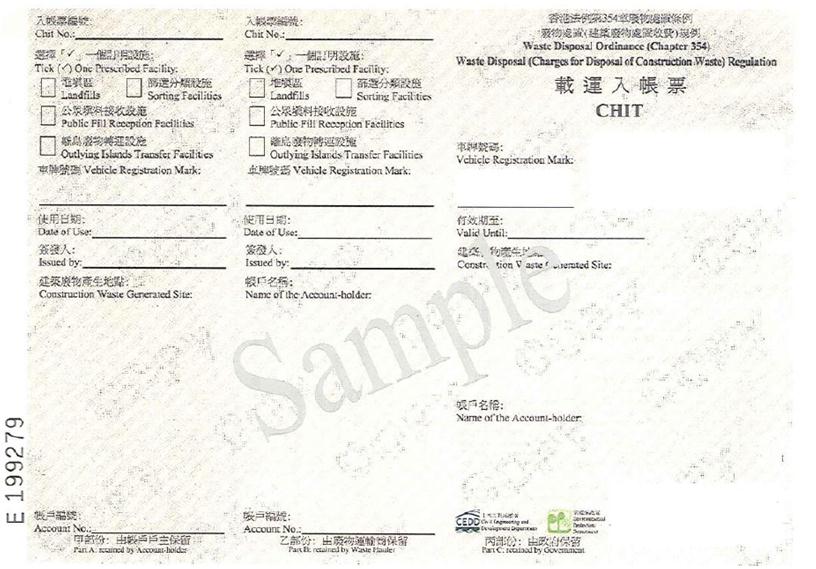

Appendix J

Sample of CHIT Form

Appendix K

Protocol of Guidelines to Dump Truck Drivers

Appendix L

Sample of Daily Record Summary

Appendix

M

Environmental Mitigation Implementation Schedule for Waste

Management

Environmental

protection and sustainable development are part and parcel of the daily

operations of the Gammon Construction Limited (referred to hereinafter as the

GCL). GCL will initiate appropriate

actions in order to minimize, and where possible eliminate, the environmental

impact arising from the construction of this project.

Gammon

Construction Limited (GCL) has been awarded of the Contract No. HY/2012/07 –

Tuen Mun Chek Lap Kok Link – Southern

Connection Viaduct Section for Highways Department (HyD) of the Government of the Hong Kong Special

Administrative Region (HKSARG). The

Works to be executed comprise the design and construction of a dual 2-lane

elevated carriageway between the HZMB HKBCF and North Lantau Highway (NLH) with associated slip roads, as well as

modifications and realignment of sections of the NLH and

The Waste

Management Plan (WMP) has been prepared to describe the arrangements for

minimising the generation of construction and demolition (C&D) materials and

disposing of the surplus C&D materials during the course of the Works.

This

contract-specific WMP shall be deposited to the Director of Environmental

Protection in accordance with the Condition 2.10 of the

Environmental Permit No. EP-354/2009/A..

The WMP shall address the potential and actual

impacts and necessary mitigation measures in light of the preferred construction

programme and consists of the following:-

·

A review

of the ordinances, regulations, codes of practices as well as contractual

obligations that are applicable to the wastes arising from the

Works;

·

An

organisation chart setting out the roles and responsibilities of the GCL’s

personnel responsible for waste management and appropriate mitigation

measures;

·

An

analysis of timing, quantities and types of C&D materials are anticipated to

be generated in the course of the execution of the Works;

·

A

classification of C&D materials into inert portion (Public Fill) and

non-inert portion (C&D Waste);

·

Proposals for avoiding/minimizing, handling, recycling, reuse,

return, storage and disposal of C&D materials, chemical waste and general

refuse;

·

An

appraisal of the potential establishment on site of a sorting facility,

including the identification of potential area on-site of facilitate the waste

sorting;

·

A

proposal for maintaining the site in a clean and tidy

condition;

·

A

monitoring and auditing proposal to ensure that the requirements of the WMP are

properly implemented.

The principles of waste

management adopted in this project shall be in line with Gammon

Table 3.1 Core

Elements of Waste Management

|

Elements |

Ref.

Section |

|

Legislation and

Guidelines License or Permit

Requirements Project

Organisation Individual Duties and

Responsibilities Classification of Waste

& Control Measures Waste Monitoring and

Auditing Training Mitigation Measures in

EIA Mitigation Measures in EM&A

Manual |

4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 |

The various waste management options shall be categorised in terms of

preference from an environmental viewpoint. The options considered to be more

preferable have the least impacts and are more sustainable in the longer

term. Hence, the hierarchy of waste

management is as follows:

·

Avoidance and

minimisation, i.e. not generating waste through changing or improving practices

and design;

·

Reuse of

materials, thus avoiding disposal;

·

Recovery and

recycling, thus avoiding disposal; and

·

Treatment and

disposal, according to relevant laws, guidelines and good

practice.

This hierarchy shall be used to evaluate waste management options, thus allowing maximum

waste reduction. Waste reduction

measures shall be introduced at the detailed planning stage and carried through

the construction activities, whenever possible, by careful purchasing control,

reuse of formworks and good site management. By reducing or eliminating over-ordering

of construction materials, waste is avoided and costs are reduced both in terms

of purchasing of raw materials and in disposing of

wastes.

The following legislation covers, or has some bearing upon, the

storage, collection, treatment and disposal of wastes in

·

Foreshore and Sea-bed (Reclamations) Ordinance (Cap

127);

·

Waste

Disposal Ordinance (Cap 354);

·

Waste

Disposal (Chemical Waste) (General) Regulation (Cap

354);

·

Land

(Miscellaneous Provisions) Ordinance (Cap

28);

·

Public

Health and Municipal Services Ordinance (Cap 132) – Public Cleansing and

Prevention of Nuisances (Urban Council) and (Regional Council) By-laws;

and

·

Dumping

At Sea Ordinance (Cap 466).

Other guiding documents which detail how the GCL should comply with

the regulations are as follows:-

·

Waste Reduction Framework Plan, 1998 to

2007,

Planning, Environment and Lands Bureau, Government Secretariat (5 November

1998);

·

2001 Review of the Waste Reduction Framework

Plan, Waste Reduction Committee;

·

Site Practice for Waste Reduction in

Construction Industry

(2001), Environmental Protection

Department;

·

Environmental Guidelines for Planning in Hong

Kong

(1990), Hong Kong Planning and Standards Guidelines,

·

New Disposal Arrangements for Construction

Waste

(1992), Environmental Protection Department & Civil Engineering

Department;

·

A Guide to the Registration of Chemical Waste

Producers (2001), Environmental Protection

Department;

·

Code of Practice on the Packaging, Labelling

and Storage of Chemical Wastes

(1992), Environmental Protection Department;

·

A Guide to the Control on Import and Export

of Waste

(1999), Environmental Protection Department;

·

Works

Bureau Technical Circular No. 10/92, Provision of Refuse Containment Booms in

Reclamation Contracts Involving Public Dumping, Works

Bureau;

·

Works

Bureau Technical Circular No. 2/93, Public Dumps, Works

Bureau;

·

Works

Bureau Technical Circular No. 2/93B, Public Filling Facilities, Works

Bureau;

·

Works

Bureau Technical Circular No. 16/96, Wet Soil in Public Dumps, Works

Bureau;

·

Works

Bureau Technical Circular No. 4/98 and 4/98A, Use of Public Fill in Reclamation

and Earth Filling Projects, Works Bureau;

·

Works

Bureau Technical Circular No. 25/99, 25/99A and 25/99C, Incorporation of

Information on Construction and Demolition Material Management in Public Works

Sub-committee Papers, Works Bureau;

·

Works

Bureau Technical Circular No 12/00, Fill Management; Works Bureau;

·

Works

Bureau Technical Circular No 19/01, Metallic Site Hoardings and Signboards,

Works Bureau;

·

Works

Bureau Technical Circular No 6/02 and 6/02A, Enhancement Specification for Site

Cleanliness and Tidiness, Works Bureau;

·

Works

Bureau Technical Circular No 12/2002, Specification Facilitating the Use of

Recycled Aggregates, Works Bureau;

·

Works

Bureau Technical Circular No 24/2004, Specification Facilitating the Use of the

Concrete Paving Units Made of Recycled Aggregates, Works

Bureau;

·

Environment, Transport and Works Bureau Technical Circular (Works) No

33/2002, Management of Construction and Demolition Material including Rock,

Environment, Transport and Works Bureau;

·

Environment, Transport and Works Bureau Technical Circular (Works) No

34/2002, Management of Dredged/Excavated Sediment, Environment, Transport and

Works Bureau;

·

Environment, Transport and Works Bureau Technical Circular (Works) No

15/2003, Waste Management on Construction Sites, Environment, Transport and

Works Bureau;

·

Environment, Transport and Works Bureau Technical Circular (Works) No

19/2005, Environmental Management on Construction Sites, Environment, Transport

and Works Bureau; and

·

Development Bureau Technical Circular (Works) No 6/2010, Trip-ticket

System for Disposal of Construction and Demolition Material, Development

Bureau.

Under the Waste Disposal (Chemical Waste) (General) Regulation, producers of chemical wastes must have

registration with Environmental Protection Department. The registration shall be applied for as

required.

The Land (Miscellaneous Provisions) Ordinance requires that dumping

licences are obtained by individuals or companies who deliver inert portion of

construction and demolition material (i.e. Public Fill) to Public Filling Areas.

The licences are issued by Civil Engineering Department under delegated powers

from the Director of Lands. The license shall be applied for as

required.

The Dumping at Sea Ordinance requires that dumping permits are

obtained by individuals or companies who deliver dredged/excavated marine

sediment to designated disposal sites. The permits are issued by Environmental

Protection Department under delegated powers from the Director of Environmental

Protection.

A billing account shall be opened with EPD prior to using Government

waste disposal facilities. Waste

shall be handled, transported, disposed and paid for in accordance with the

Charging Scheme.

The organisational

structure for environmental management are in-line with the project management

during the course of the Works is presented in Appendix B, which identifies the major parties

with environmental responsibilities and illustrates their lines of

communication. Descriptions on the roles and responsibilities of these parties

are provided in the following sub-sections. The contact list for the

representatives of the concerned parties is given in Appendix C.

He is responsible to GCL’s

Executive Directors for overall planning, contract review, appointment of Site

Health Safety & Environmental (HS&E) Representative and other site

members for environmental matters.

He will ensure provision of adequate resources to address environmental

matters for the Project.

The Project Director has the following

responsibilities in relation to waste management:

-

·

Approving the

WMP;

·

Maintaining the overall control

of the Contract and oversee the implementation of the

WMP;

·

Ensuring that adequate resources

are provided for the efficient implementation of

WMP;

·

Reporting to Senior Management

of Company on all environmental matters whenever necessary;

and

·

Ensuring compliance of all

relevant waste management legislation throughout the duration of the

Contract..

The

Project Manager has the following responsibilities in relation to waste

management: -

·

the day-to-day overview of site

practices in relation to waste management;

·

directing Section Agents,

General Foremen and Foremen as appropriate in supervising and enforcing the

on-site mitigation measures;

·

reporting to the PM;

and

·

ensuring all waste records be

promptly available to the Environmental Manager for record and/or action as

necessary

Site Engineers/Site Agents/Foremen are

responsible for the following duties in relation to environmental

control:

·

coordinating waste management on

site, gather data about waste and keep up-dated record of waste movement on and

off site;

·

obtaining a list of potential

buyers or collectors of waste to be reused or recycled;

and

·

investigating potential re-use and

recycle opportunities of waste.

Site Agents/Foremen are responsible for the

following duties in relation to environmental

control:

·

assisting Environmental Manager

in all aspects of required waste management on

site;

·

supervising and monitoring the

works of workers including subcontractors in relation to waste management;

and

·

ensuring all waste containers and

storage areas are properly labelled.

The

Environmental Manager shall oversee the implementation and the performance of

the WMP and shall also be responsible

for:

·

the day-to-day overview of site

practices in relation to waste management on

site;

·

applying all necessary licences

in relation to waste

management;

·

reporting to the

PM;

·

coordinate with the Construction

Manager to ensure proper implementation of mitigation measures on waste

management;

·

conducting meetings/ briefings/

inductions/ tool-box talks with all sub-contractors, direct contractors,

specialist contractors, utility undertakers and employees to enhance

understanding of aims and contents of WMP;

and

·

preparing and submitting the Monthly

Summary Waste Flow Table (WFT), Yearly Summary WFT and Summary Table for Work

Processes or Activities Requiring Timber for Temporary

Works.

The

Environmental Officer/ Engineer shall assist the Environmental Manager to

oversee the implementation and the performance of the WMP and shall also be

responsible for:

·

assisting EnvM to disseminate information and requirement to the site

operative in connection with the implementation of the waste management

on-site;

·

monitoring the WMP

implementation, carrying out site

surveillance;

·

keeping environmental related

documents as well as assisting on training staff at different

levels;

·

assisting in the review and

update of the WMP, the Waste Flow Tables (WFT) and the summary table for the use

of timber during temporary works construction;

and

·

working closely with Site Engineers to

ensure the Contract is carried out in compliance with all waste related

contractual and legal requirements..

Site-resident

Environmental Supervisor (ES) will be appointed by the GCL. The duties of the

ES’s will include but not limited to the

following:

(a)

Assist the EO/ EE in carrying

out his duties;

(b)

Carry out daily site

environmental inspections based on a checklist approved by the SOR, and to

ensure that follow-up actions have been taken promptly against defects and

deficiencies identified;

(c)

Advise the EO/ EE on the upkeeping of environmental performance and standards of the

Site;

(d)

Attend the weekly environmental

walk;

(e)

Supervise and promote the

execution of environmental work on the Site;

(f)

Attend SSEMC meetings and SSEC

meetings; and

(g)

Conduct toolbox talks as

assigned by the GCL’s Agent after acquiring the

necessary.

The ET /ETL shall be an

independent environmental consultant from GCL. The ET

shall:

·

maintaining overall control of

the monitoring and professional

services;

·

reporting directly to the

Environmental Manager;

·

providing assistance and

guidance to the Contractor in the implementation of

WMP;

·

identifying the potential

hazardous waste whenever possible and take proactive actions before problems

arise;

·

providing briefing to the

project team as necessary on the waste management requirements;

and

·

carrying out Waste Management

Audit.

Every employee and subcontractor has the duty to carry out agreed

waste management practices as instructed by the Site Agent / Site Engineer.

Their duties are:

·

observing and implementing the

measures set out by this WMP;

·

following all environmental

related instructions given by the management staff of

GCL;

·

reporting any non-compliance of

the waste management measures; and

·

conducting the rectifying actions as

required in a timely and efficient manner.

The waste generated from the construction activities shall be divided

into distinct categories based on their composition, as follows:

(a) Construction and demolition (C&D)

materials

(i)

Inert C&D materials

(ii)

Non-inert C&D materials

(b) Chemical wastes

(c) General refuses

(d) Dredged marine sediments

(i) Uncontaminated marine sediments (Cat. L

)

(ii)

Contaminated marine sediments (Cat. Mp

& Mf)

A

quantities of

excavated materials to be generated, reuse on- or offsite during works has been

estimated and shown in Appendix D.

The estimated quantities, types of the C&D materials and corresponding

disposal grounds will be updated monthly and indicated in the monthly programme for disposal of C&D materials, which will be

reported to the SOR via submissions of monthly waste flow tables as shown in Appendix

E. All

anticipated disposal scenarios and transportation modes are summarized in Appendix

F.

C&D materials comprise unwanted

materials generated during construction, including rejected structures and

materials, materials which have been over ordered or are surplus to

requirements, and materials used and discarded.

C&D material could be divided into two

categories according to whether they are inert or non-inert. Inert C&D

material are known as rock, rubble, boulder, earth, soil, sand, concrete,

asphalt, brick, tile, masonry and used bentonite,

where to be maximized the reuse of these materials within the Contract and to be

disposed of the surplus of these materials to other Contracts, subjected to the

approval or direction of Supervising Office Representative (SOR). Under any

circumstances that no site is able to receive the unsuitable C&D materials

for the filling purpose, GCL will apply to CEDD for the public fill reception

facilities (PFRF) as a back-up option.

Non-inert C&D material

are such as metal, timber, vegetation, packaging waste, organic material and all

recyclables and non-recyclables is called “C&D Waste”. C&D waste,

excluding recyclables, shall be disposed of at NENT

Landfill.

Recyclables are mainly metals, paper/cardboard packaging and

plastics. Plastics refer to plastic bottles/containers, plastic sheets/foam from

packaging material. Recyclables would be collected by

relevant recyclers. Non-recyclable materials are treated as general

refuse.

The following general low waste construction

designs and principles together with careful planning shall be adopted to

avoid/minimise C&D material generation. Such measures include:

-

(a)

Management of construction materials such that over-ordering, poor

storage and maintenance, mishandling as well as improper operation procedures

shall be avoided.

(b)

Restriction on use of hardwood such that softwood, metal props and/or

proprietary steel system shall be considered for false work and the shoring of

trenches and pits;

(c)

The

formwork shall be designed to maximise the use of standard wooden panels so that

high reuse levels can be achieved.

More durable alternatives such as steel formwork or plastic facing shall

be considered for repetitive areas to increase the potential for reuse.

(d)

C&D materials shall be, as much as possible and practicable,

separated into reusable items and materials to be disposed of or recycled. It

shall be conducted at the immediate working area to avoid loss/leakage and cross

contamination during handling.

(e)

All

C&D materials arising from or in connection with the construction and

demolition work shall be sorted on-site and be separated into different

categories for disposal at landfills, public filling areas, or reuse and

recycling as appropriate. The

sorting area may be revised from time to time in order to suit the construction

activities.

(f)

Useful materials such as timber, rubble and steel/metal shall be

segregated for reuse. For example formwork and timber shall be cleaned for

reuse, off-cuts of reinforcement shall be sorted into usable lengths and short

off cuts stacked for scrap metal.

Where it is no longer reusable, scrap steel and metal items will be

collected by recycling companies.

(g)

Segregated materials shall be temporarily stored at designated areas

for reuse on site. Steel will be stored at the reinforcement yards, timber at

the formwork yard and rubble in a stockpile (either covered or sprayed to

control dust). Cardboard and paper

packaging recovered from site shall be properly stockpiled in dry condition and

covered.

(h)

In order to avoid over-order of concrete, accurate calculation shall

be made prior to concrete pouring.

Close supervision shall also be arranged during concrete pouring to avoid

over-cast.

(i)

Surplus concrete shall be used for paving of temporary road or cast

of concrete blocks for bunding etc. as far as

practicable. In case immediate use

of surplus concrete cannot be identified, the surplus concrete will be

temporarily poured into designated surplus concrete pouring areas on site for

further disposal to public filling areas.

(j)

Entirely cover every stock of more than 20 bags of cement by

impervious sheeting and carry out the de-bagging, batching and mixing processes

in an area sheltered on the top and the 3 sides.

Damp and gather the waste cement bags for proper

disposal.

(k)

Used

bentonite shall only be disposed of at Public Fill

area.

GCL designate suitable

areas onsite for the storage, sorting and segregation of construction

waste. The areas that are

designated by GCL will be clearly defined with appropriate signage and barriers

(or similar) and allow for easy access by workers and vehicles. As the project progresses it is

anticipated that the designated areas will be reviewed depending upon

construction program requirements.

The areas designated by GCL will be sufficient for the amounts of

construction waste that are anticipated to be generated during the course of the

contract. The sorting mechanism is shown in Table 8.1. The tentative locations for the

temporary storage and sorting of C&D waste are shown in Appendix G.

Table 8.1

Sorting of C&D Materials

|

Type of C&D

Material |

Required Action |

|

Rock |

Reuse on site where possible or recycle off

site |

|

Excavated material |

Reuse on site where possible or dispose of at approved landfill

facility |

|

Excavated Marine

Deposits |

Dispose of offsite at approved

location |

|

Concrete |

Sorted and segregated onsite, reuse on site where possible or

recycle offsite |

|

Metal |

Segregate and recycle

offsite |

|

Paper/Cardboard

Materials |

Segregate and recycle

offsite |

|

Plastics |

Use recycling containers and recycle

offsite |

|

Aluminium Cans |

Use recycling containers and recycle

offsite |

|

Timber |

Reuse on site if possible, other segregate and recycle off

site |

|

Chemical Waste |

Store in approved containers and transport offsite for disposal

at an approved facility |

Chemical wastes are the substances defined by the Schedule 1 of the Waste Disposal (Chemical Waste) (General)

Regulation. Chemical wastes generated from the

construction sites will primarily arise from the maintenance of plant and

equipment. These may typically include oils, lubricants, paints and solvents.

Containers used for the storage of chemical waste

shall:

·

be

suitable for the substance they are holding, resistant to corrosion, maintained

in a good condition, and securely closed;

·

have a

capacity of less than 450 litres unless the specification have been approved by

the EPD; and

·

display a

label in English and Chinese in accordance with instruction prescribed in Schedule 2 of the Waste Disposal

(Chemical Waste)(General) Regulation.

The storage area for chemical wastes

shall:

·

be

clearly labelled and used solely for the storage of chemical

waste;

·

be

enclosed on at least three sides;

·

have an

impermeable floor and bunding, of capacity to

accommodate 110% of the volume of the largest container or 20% by volume of the

chemical waste stored in that area;

·

have

adequate ventilation;

·

be

covered to prevent rainfall entering (water collected within the bund must be

tested and disposed as chemical waste if necessary);

and

·

be

arranged so that incompatible materials are adequately

separated.

Disposal of chemical waste shall:

·

be via a

licensed waste collector;

·

be to an

off site facility licensed to receive chemical waste,

such as a recycling facility located in Yuen Long Industrial Estate or the

Chemical Waste Treatment Facility located in Tsing

Yi.

A

Spill Response Plan shall be prepared separately and implemented to deal with

any accidental spillage of chemicals on site. The spill response plan should contain

procedures for:

·

Spill

prevention and precaution

·

Response

actions

·

Spill

clean up and

disposal

General

refuses include food wastes, non-recyclable materials (including waste

paper/cardboard packaging, plastics and timber) and other debris arising from

various construction activities, site workforce and site

housekeeping.

General refuses shall be disposed of at NENT Landfill.

Measures that encourage waste

avoidance/minimization

include:

·

Reducing the number of photo copies to a minimum and by copying on

both sides of paper for internal documents and external documents where

appropriate;

·

Preventing over-ordering of office equipment and

consumables;

·

Procuring green office equipment and consumables in terms of energy

efficiency, recycled content and durability, etc;

·

Providing drinking facility and encouraging employees to bring their

own cup; and

·

Discouraging take-out food.

Additional measures that facilitate

reuse/recycling

and orderly disposal include:

·

Deploying sufficient recycle bins at convenient locations to

facilitate collection of recyclables including wasted aluminium cans, plastic

bottles and cardboard and papers packaging;

·

Deploying sufficient refuse collection bin at convenient locations to

facilitate collection of non-recyclables for disposal at landfills;

and

·

Participating local collection scheme (e.g. scheme launched by

District Board) if available.

Marine

sediment means excavated from the Works of the foundation and associated

substructures at the sea. It could be classified as

contaminated and uncontaminated based on its contamination level with reference

to Chemical Exceedance Level (CEL) laid down in the

Appendix A of the ETWB TCW No. 34/2002. The excavation and disposal of marine sediments

generated shall be minimized from the Works in this

Contract,

e.g. only from the excavation of the foundation and the associated substructures

such as the piles, pile caps and piers. In events that dredging/ excavation of

marine sediment are unavoidable, the GCL shall handle/ process such marine

sediment in accordance with the procedures given in ETWB TCW No. 34/2002. GCL

will apply to the EPD for all valid permits and licenses in accordance with only

dispose of the marine sediment at the designated disposal facilities as directed

by the Director of Environmental Protection and/or the Marine Fill Committee

(MFC) unless otherwise agreed or ordered in writing by the Supervising Officer.

The copy of memo from Marine Fill Committee of CEDD granting the allocations for

the sediment disposal space is attached in Appendix

H.

In case of disposal of any amount of the marine sediment in Hong Kong

waters, the dumping of sediments shall be strictly within the designated

sediment disposal sites and shall be controlled through a dumping permit issued

under the Dumping at Sea Ordinance (Cap 466), or called a DASO permit, by the

Director of Environmental Protection. Dumping shall take place at sub-areas

within the sediment disposal sites, the locations of which will be changed from

time to time as notified by the Director of Environmental Protection through the

Supervising Officer.

Subject to the instruction of SO, notwithstanding whether the GCL

elects to dispose of any or all dredged/excavated marine sediments at the

designated sediment disposal sites in Hong Kong, the GCL will apply for approval

to relevant authorities in Mainland and Hong Kong for the cross-boundary

disposal of Cat. L and Mp

sediments at the tentative disposal site of South Dangan Liedao (擔杆列島). This cross-boundary disposal option shall only

proceed with the Supervising Officer’s instruction. In the event that the

approval of cross-boundary disposal is not obtained in a timely manner, Cat. L and Mp sediments

would be arranged to dispose of at South Cheung Chau Open Sea Sediment Disposal

Area and East Sha Chau or South of the Brothers Marine Sediment Disposal

Facility as a fallback option to be authorized by

Supervising Officer, EPD and CEDD-MFC.

In

cases that off-site disposal of marine sediment in Hong Kong Water required, GCL

shall apply for the allocation of a sediment disposal site in the name of

Highways Department of the HKSAR, and marine loading permits under Dumping at

Sea Ordinance (Cap. 466) (DASO) for the disposal of marine sediment at the

designated disposal facilities in Hong Kong.

The marine sediment of Category M failing

biological tests as defined in ETWB TC(W) No. 34/2002 shall be disposed of

in

CEDD-MFC's designated contaminated mud pits in Hong Kong waters, at mud pit of

East Sha Chau or South of the Brothers Marine Sediment Disposal Facility as

allocated

by CEDD-MFC. GCL shall place the contaminated mud at a location and in a manner

as directed on site by the CEDD management team. GCL shall proceed with the

disposal operation as instructed by the management team and in accordance with

the relevant sections of the Requirements of the Contaminated Mud Pit Management

Scheme which may be modified from time to time by the management team. GCL shall

not carry out any dumping without permission of the management team or when the

management team is not in operation. GCL will carry out the dumping operation in

strict accordance with the method statement agreed by the Licensing

Authority.

In accordance with DEVB TC(W) No. 6/2010,

with tender invitation was on or after 1 November 2010, the administration of

CHIT/ DDF was streamlined. CHIT in lieu of the bar-coded Disposal Delivery Form (DDF) should be used at

all prescribed facilities, i.e. public fill reception facilities,

sorting facilities, outlying island transfer facilities and landfills. Moreover,

under the Construction Waste Disposal Charging Scheme, GCL registered with EPD a

disposal account and will adopt the CHIT as the enhanced control of C&D

material disposal. The control procedure on off-site disposal of C&D

materials is shown in Appendix I. The sample of CHIT is given in Appendix

J.

Every C&D material disposal trip to the public fill reception

facilities and designated landfill shall be controlled under the trip-ticket

system as per the DEVB TC(W) No. 6/2010 in order to

avoid fly-tipping. Appendix G gives the site procedure for the TTS operation.

For disposal of chemical wastes, the trip-ticket system as per the

Waste Disposal (Chemical Waste) Regulation in which licensed collector will be

employed and the chemical wastes be disposed of at

designated chemical waste treatment facility.

GCL will inform all truck drivers engaged for removal

of C&D materials from the Site of the

following particular points:

·

Each truck carrying C&D

materials leaving the Site for a disposal ground must bear a duly completed

CHIT, irrespective of the location and nature of the disposal ground;

and

·

The C&D materials must be

disposed of at the disposal grounds stipulated in the Contract or directed by

the SOR or alternative disposal grounds approved by the

SOR.

GCL

would formulate a guiding protocol for truck

drivers being engaged and give all of them a copy for their information. Where

necessary, a tool box talk relating to the protocol will be given to all engaged

driver. The protocol is shown in Appendix

J.

GCL

shall arrange weekly inspection attended by the Environmental Officer and SOR to

inspect the site to ensure satisfactory performance on compliance with the WMP

with due regards to the followings:

(a)

Inert

C&D materials suitable for recycling into aggregates are recovered and

delivered to Tuen Mun Area

38 or other designated recycling facilities as notified by the

SOR or

the Public Fill Committee (Port Works Division of CED);

(b)

A

disposal recording system is operating satisfactorily for recording C&D

materials removed from the Site;

(c)

On-site sorting of C&D materials is properly carried out to

recover inert C&D materials and reusable and/or recyclable materials before

disposal;

(d)

Paper/cardboard packaging, and metals including aluminium cans are

recovered and collected; and

(e)

Plastic

bottles/containers or plastic sheets/foam from packaging are collected as far as

possible for recycling.

GCL may

arrange the

weekly inspection on waste management performance to be carried out along with

the weekly safety walks for safety or other site

inspections.

GCL shall prepare and agree with the SOR a comprehensive checklist for use during weekly inspections on waste

management. The defects or deficiencies identified during the weekly inspection

on waste management together with their respective locations and the

corresponding due dates for rectification as set by the

SOR nominated site representative should be entered in a summary table

of follow-up actions similar to the one established for weekly safety walks for

monitoring of the rectification progress. GCL may need to prepare more than one

comprehensive checklist to suit the variety of works at various portions of the

Site. It is recommended that items

covered in the checklist should primarily

address:-

(a)

the physical conditions of the Site (e.g. housekeeping, site tidiness

and cleanliness, etc.);

(b)

the adequacy of measures applied to each category of waste;

and

(c)

the availability/accessibility/maintenance of waste management

facilities.

Immediately after the weekly inspection, the

summary table of follow-up actions shall be agreed and signed by both the

assigned person and the SOR and a copy should be kept by the

SOR for monitoring of the progress of rectification and for payment. GCL

shall take prompt action to rectify the deficiencies identified and shall report

the status of action taken before the forthcoming weekly inspection.

Should deficiency

with regard to

waste management affairs persists,

the Event Contingency Plan as detailed below shall be triggered. Non-compliance shall include the

following situations:

·

Infringement of legal requirements with respect to waste issues.

·

Persistent outstanding of control measures stated in the WMP as

identified during the site inspection or

audit.

·

Overloading of dump truck

Table 9.1

Action Plan for Non-Compliance

|

Day |

Action |

GCL |

SOR | |

|

1. |

1 |

Create a new non-compliance record within 1 working day after

making an observation during a site audit accompanied by Environmental

Officer or his delegate.

Environmental Officer sends a Notice of Non-Compliance (NNC) to the

Project Manager / Site Agent.

The NNC would include the observations and the reasons for

non-compliance. |

|

|

|

2. |

2 |

Propose corrective actions within 1 working day after the

receipt of the NNC. |

|

|

|

3. |

2 |

Review and agree with the proposed corrective actions and make

additional recommendations as

required. |

|

|

|

4. |

2 |

Implement the proposed corrective actions once they have been

agreed. |

|

|

|

5. |

- |

Check the implementation of the corrective actions at the next

site audit. Close the

non-compliance record if the implementation of the corrective actions is

satisfactory. |

|

|

|

6. |

- |

Propose preventive actions within 3 working days after the

closure of the non-compliance

record. |

|

|

![]() Action

party

Action

party

![]() Comments on the

non-compliance record where applicable.

Comments on the

non-compliance record where applicable.

ET shall check whether GCL has followed the relevant contract

specifications and the procedures specified under the laws of

Table 9.2 Waste

Management Checklist

|

Activities |

Timing |

Monitoring

Frequency |

If

non-compliance, Action Required |

|

All

necessary waste disposal permits or licences

have been obtained |

Before

the commencement of demolition

works |

Once |

Apply

for the necessary permits/ licences prior to

disposal of the waste. The ET shall ensure that corrective action has been

taken. |

|

Only

licensed waste haulier are used for

waste collection. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to use a licensed waste haulier.

The Contractor shall temporarily suspend waste collection of that

particular waste until a licensed waste haulier

is used. Corrective action shall be undertaken within 48

hours. |

|

Records

of quantities of wastes generated, recycled and disposed are properly

kept. For demolition material/waste, the number of loads for each day

shall be recorded (quantity of waste can then be estimated based on

average truck load. Should landfill charging be implemented, the receipts

of the charge could be used for estimating

the quantity). |

Throughout

the works |

Weekly |

The

Contractor shall estimate the missing data based on previous records and

the activities carried out. The ET shall audit the results and forward to

the ER and IEC for approval. |

|

Wastes

are removed from site in a timely manner. General refuse is collected on a

daily basis. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to remove waste

accordingly. |

|

Waste

storage areas are properly cleaned and do not cause windblown litter and

dust nuisance. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to clean the storage area and/or cover the

waste. |

|

Different

types of waste are segregated in different containers or skip to enhance

recycling of material and proper disposal of

waste. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to provide separate skips/ containers. The Contractor shall

ensure the workers place the waste in the appropriate

containers. |

|

Chemical

wastes are stored, handled and disposed of in accordance with the Code of

Practice on the Packaging, Handling and Storage of Chemical Wastes,

published by the EPD. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to rectify the problems immediately. Warning shall be given

to the Contractor if corrective actions are not taken within 24 hrs and the Waste Control Group of the EPD shall be

identified. |

|

Demolition

material/waste in dump trucks are properly

covered before leaving the

site. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall instruct

the Contractor to comply. The Contractor shall prevent trucks shall

leaving the site until the waste are properly

covered. |

|

Wastes

are disposal of at licensed

sites. |

Throughout

the works |

Weekly |

The

ET shall inform the ER and IEC of the noncompliance. The ER shall warn the

Contractor and instruct the Contractor to ensure the wastes are disposed

of at the licensed sites. Should it involve chemical waste, the Waste

Control Group of EPD shall be

notified. |

GCL shall keep adequate and proper records such as delivery dockets and measurement records relating to

the implementation of the WMP. The

records shall include trip-ticket, completed inspection checklists and training

records.

Daily Record Summary (DRS) shall be filled by designated persons.to

record every truck for delivery of C&D materials. The sample of DRS is given

in Appendix

L.

As

part of the WMP,

a mechanism

shall be established to record the quantities of C&D materials generated

each month, using the monthly summary “Waste Flow Table” (WFT) as given in Appendix

E.

Estimated quantities of

C&D materials that will be generated each year from the site the GCL should

also be provided, using the yearly summary WFT as given in Appendix

D. The yearly summary WFT covering the whole construction period

shall be included in the WMP and updated on yearly basis, throughout the

construction period in order to account for the revised works programme and

latest outturn on the quantities of C&D materials generated from the

site.

To ensure the effectiveness

of the Trip-Ticket System, the following item will be discussed at every Site

Safety and Environmental Management Committee meeting, and Site Safety and

Environmental Committee meeting or ad-hoc meetings on as-needed

basis:

1. Review the site management plan

and implementation of the TTS, and identify areas for

improvement;

2. Audit the quantity of C&D

materials removed from the Site (based on the DRS and survey records) against

the quantities of C&D materials delivered to the disposal ground designated

in the Contract (e.g. based on EPD website) and directed or approved by the

Supervising Officer;

3. Review incidents of

non-compliance and discuss the necessary follow-up actions for TTS;

and

4. Monitor the follow-up action on

defects and deficiencies

identified.

The Environmental Officer and other site personnel (if they have not attended similar course

before) shall be arranged to attend training on waste management organised by

training institutes or organisations as considered

appropriate.

The Environmental Officer shall arrange and provide training on waste

management in the site-specific induction and its refresher training for all

persons employed by the GCL or his subcontractor on the Works or in connection with the Contract. The training should

cover the waste management policy, targets, measures for on-site sorting of

C&D materials and measurement on waste management performance on the Site.

According to ER requirement, induction training shall be carried out within

first 2 days of the employment and refreshment training shall be carried out by

every 6 months.

The Environmental Officer is allowed to develop and provide toolbox

talks for the topic on on-site sorting of C&D materials to promote the workers

The Section 12.6 of the EIA Report gives recommendations on

mitigation measures of waste management. The recommendations were extracted to

form an implementation schedule particularly for waste management during

construction phase and the schedule is shown in Appendix

M.

The Section 8.1.2 of the EM&A Manual gives recommendations on

mitigation measures of waste management, which

are:

·

The waste management hierarchy below should be strictly followed.

This hierarchy should be adopted to evaluate the waste management options in

order to maximise the extent of waste reduction and cost reduction. The records

of quantities of waste generated, recycled and disposed (locations) should be

properly documented.

·

A trip-ticket system should be established in accordance with

DEVB TC(W) No.

6/2010 and Waste Disposal (Charges for Disposal of Construction Waste)

Regulation to monitor the disposal of public fill and solid wastes at public

filling facilities and landfills, and to control fly-tipping. A trip-ticket

system would be included as one of the contractual requirements for the

Contractor to strictly implement. The Engineer would also regularly audit the

effectiveness of the system.

·

A recording system for the amount of waste generated, recycled and

disposed (locations) should be established. The future Contractor should also

provide proper training to workers regarding the appropriate concepts of site

cleanliness and waste management procedures, e.g. waste reduction, reuse and

recycling all the time.

·

The CEDD should be timely notified of the estimated spoil volumes to

be generated and the Public Fill Committee should be notified and agreement sort

on the disposal of surplus inert C&D materials e.g. good quality rock during

detailed design of the TM-CLKL project. Wherever practicable, C&D materials

should be segregated from other wastes to avoid contamination and to ensure

acceptability at public filling areas or reclamation

sites.

·

The extent of cutting operation should be optimised where possible.

Earth retaining structures and bored pile walls should be proposed to minimise

the extent of cutting.

·

Inert C&D materials from slopes and road pavement will be reused

for construction of the raised platform for the toll

plaza.

·

C&D materials generated by construction of cut slopes along NLH

at

·

The surplus surcharge should be transferred to a fill

bank.

·

Rock armour from the existing seawall should be reused on the new

sloping seawall as far as possible.

·

The site and surroundings shall be kept tidy and litter

free.

·

No waste shall be burnt on site.

·

Make provisions in contract documents to allow and promote the use of

recycled aggregates where appropriate.

·

Prohibit the Contractor to dispose of C&D materials at any

sensitive locations e.g. natural habitat, etc. The Contractor should propose the

final disposal sites in the EMP and WMP for approval before

implementation.

·

Stockpiled material shall be covered by tarpaulin and /or watered as

appropriate to prevent windblown dust and surface run

off.

·

Excavated material in trucks shall be covered by tarpaulins to reduce

the potential for spillage and dust

generation.

·

Wheel washing facilities shall be used by all trucks leaving the site

to prevent transfer of mud onto public

roads.

·

Dredged marine mud shall be disposed of in a gazetted marine disposal

ground under the requirements of the Dumping at Seas

Ordinance.

·

Standard formwork or pre-fabrication should be used as far as

practicable so as to minimise the C&D materials arising. The use of more

durable formwork or plastic facing for construction works should also be

considered. The use of wooden hoardings should be avoided and metal hoarding

should be used to facilitate recycling. Purchasing of construction materials

should be carefully planned in order to avoid over-ordering and

wastage.

·

The Contractor should recycle as many C&D materials (this is a

waste section) as possible on-site. The public fill and C&D waste should be

segregated and stored in separate containers or skips to facilitate the reuse or

recycling of materials and proper disposal. Where practicable, the concrete and

masonry should be crushed and used as fill materials. Steel reinforcement bar

should be collected for use by scrap steel mills. Different areas of the sites

should be considered for segregation and storage

activities.

·

All falsework will be steel instead of

wood, as far as possible.

·

Chemical waste producers should register with the EPD. Chemical waste

should be handled in accordance with the Code of Practice on the Packaging,

Handling and Storage of Chemical Wastes as

follows:

-

Suitable for the substance to be held, resistant to corrosion,

maintained in good conditions and securely

closed;

-

Having a capacity of <450L unless the specifications have been

approved by the EPD; and

-

Displaying a label in English and Chinese according to the

instructions prescribed in Schedule 2 of the

Regulations.

-

Clearly labelled and used solely for the storage of chemical

wastes;

-

Enclosed with at least 3 sides;

-

Impermeable floor and bund with capacity to accommodate 110% of the

volume of the largest container or 20% by volume of the chemical waste stored in

the area, whichever is greatest;

-

Adequate ventilation;

-

Sufficiently covered to prevent rainfall entering (water collected

within the bund must be tested and disposed of as chemical waste, if necessary);

and

-

Incompatible materials are adequately

separated.

·

Waste oils, chemicals or solvents shall not be disposed of to

drain;

·

Adequate numbers of portable toilets should be provided for on-site

workers. Portable toilets should be maintained in reasonable states, which will

not deter the workers from utilising them. Night soil should be regularly

collected by licensed collectors.

·

General refuse arising on-site should be stored in enclosed bins or

compaction units separately from C&D and chemical wastes. Sufficient

dustbins shall be provided for storage of waste as required under the Public

Cleansing and Prevention of Nuisances By-laws. In addition, general refuse shall

be cleared daily and shall be disposed of to the nearest licensed landfill or

refuse transfer station. Burning of refuse on construction sites is

prohibited.

·

All waste containers shall be in a secure area on hard standing;

Aluminium cans are usually collected and recovered from the waste stream by

individual collectors if they are segregated and easily accessible. Separately

labelled bins for their deposition should be provided as far as

practicable.

·

Office wastes can be reduced by recycling of paper if such volume is

sufficiently large to warrant collection. Participation in a local collection

scheme by the Contractor should be advocated. Waste separation facilities for

paper, aluminium cans, plastic bottles, etc. should be provided

on-site.

·

Training shall be provided to workers about the concepts of site

cleanliness and appropriate waste management procedure, including waste

reduction, reuse and recycling.

|

APPENDIX A Gammon’s Health, Safety and

Environmental Policy |

|

APPENDIX

B Organisation Structure for Environnemental

Management |

APPENDIX C Contact

List |

|

Contact List |

Telephone

No. |

|

Project Proponent – Highway Department HZMB

Office |

|

|

Employer’s Rep. – Mr. Johnny CHAN

|

2762 4976 |

|

Environmental Team - Environmental Resources Management |

|

|

Project Director – Mr. Craig A

REID |

2271 3179 |

|

ET Leader – Mr. Jovy

TAM |

2271

3113 |

|

Gammon Construction Ltd. |

|

|

Project Director – Mr. Andrew VENESS |

2750 0278 |

|

Deputy Project Director – Mr. Chris MA |

2750 0183 |

|

Engineering Director – Mr. John CLARK |

2750 0178 |

|

Senior Construction Manager – Mr. Nigel KING |

2750 0183 |

|

Construction Manager – Mr. Hans SUNDSTROM |

9300 7636 |

|

Construction Manager – Mr. W.T. HO |

6111 2176 |

|

Construction Manager – Mr. Wing LAW |

9655 0672 |

|

Project Manager – Mr. Patrick

CHAN |

9488 2979 |

|

Project Manager – Mr. K.M.

CHAING |

9360 0586 |

|

Safety

Manager – Mr. C.Y.

LAU |

9022 1273 |

|

Environmental Manager – Mr. Brian KAM |

9456 9541 |

|

Environmental

Officer – Mr. Roy

LEUNG |

6468 7650 |

|

Environmental Protection

Department |

|

|

EPO-RS(52) – Ms. Connie

WONG |

2516 1782 |

|

APPENDIX D Proforma of Yearly Summary

Waste Flow

Table |

Contract No. : HY/2012/07

Tuen Mun-Chek Lap Kok

Link – Southern Connection Viaduct

Section

Yearly Summary Waste Flow Table

Estimation

|

Year |

Estimated (Est.) Annual Quantities of Inert C&D

Materials |

Estimated (Est.) Annual Quantities of C&D

Wastes |

Estimated (Est.) Annual Quantities of

Recyclables | |||||||||||

|

(a)=(b)+(c)+ (d)+(e) Total Quantity

Generated |

(b) Hard Rock & Broken Concrete |

(c) Reused in the

Contract |

(d) Reused in other

Projects |

(e) Disposed as Public Fill (see Note

6) |

(f) Import Fill |

(g) Marine Sediment |

(h) Chemical Waste (in '000 kg) |

(i) Others, e.g. general refuse disposed at

Landfill (in |

(j) Metals (in |

(k) Paper/ cardboard

packaging |

(l) Plastics | |||

|

Cat. L |

Cat. Mp |

Cat. Mf | ||||||||||||

|

(in

'000m3) |

(in

'000m3) |

(in

'000m3) |

(in

'000m3) |

(in '000m3) |

(in '000m3) |

(in |

(in |

(in |

(in |

(in |

(in '000 kg) |

(in |

(in | |

|

Est. |

Est.. |

Est. |

Est.. |

Est. |

Est. |

Est. |

Est. |

Est. |

Est. |

Est. |

Est. |

Est. |

Est. | |

|

2013 |

53.108 |

26.554 |

26.554 |

-- |

-- |

-- |

-- |

-- |

-- |

-- |

1,000 |

-- |

2 |

-- |

|

2014 |

41.144 |

12.711 |

15.723 |

12.711 |

-- |

-- |

9.524 |

2.381 |

1.429 |

0.1 |

1,800 |

-- |

10 |

3 |

|

2015 |

58.021 |

1.63 |

56.114 |

0.277 |

-- |

-- |

10.476 |

2.619 |

1.571 |

0.1 |

1,800 |

-- |

10 |

3 |

|

2016 |

30.615 |

-- |

30.615 |

-- |

-- |

1.249 |

-- |

-- |

-- |

0.1 |

1,000 |

-- |

5 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grand Total |

182.888 |

40.895 |

129.006 |

12.988 |

-- |

1.249 |

20.0 |

5.0 |

3.0 |

0.3 |

5,600 |

-- |

27 |

9 |

Notes:

(1)

The waste flow table shall also include C&D materials that are

specified in the Contract to be imported for use at the

Site.

(2)

Plastic refer to plastic bottles/containers, plastic sheets/foam from

packaging material

(3)

Broken concrete for recycling into

aggregates

(4)

The Yearly Waste Flow Table will be updated if there is any

changed.

(5)

Highlighted in yellow for any updated

(6)

GCL would

maximize reusing C&D material as far as possible. Public fill is a fall back

option for unsuitable material disposal, if

any.

|

APPENDIX E Proforma of Monthly Summary

Waste Flow

Table |

Contract No. : HY/2012/07

Tuen Mun-Chek Lap Kok

Link – Southern Connection Viaduct Section

Monthly Summary Waste Flow Table for ________ (Year)

|

Month\Material |

Actual

Quantities of Inert C&D Materials

Generation |

Actual

Quantities of C&D wastes

Generation |

Actual

Quantities of Recyclables

Generation | |||||||||||

|

Total

Quantity Generated |

Hard

Rock and Large Broken Concrete |

Reused

in the Contract |

Reused

in other Projects |

Disposed

as Public Fills |

Imported

Fill |

Marine

Sediment, Cat. L |

Marine

Sediment, Cat. Mp |

Marine

Sediment, Cat. Mf |

Chemical

Waste |

General

Refuse |

Metals

|

Paper/

cardboard packaging |

Plastics | |

|

Unit |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000m3) |

('000Kg) |

('000Kg) |

('000Kg) |

('000Kg) |

('000Kg) |

|

Jan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Feb |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Apr |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

May |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jun |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUB-TOTAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jul |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aug |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sep |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oct |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nov |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dec |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOTAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes:

1

- The waste flow table shall also include C&D materials that are specified

in the Contract to be imported for use at the

Site.

2

- Plastics refer to plastic bottles/containers, plastic sheets/foam from

packaging material.

3

- Broken concrete for recycling into

aggregates.

|

APPENDIX F Disposal Scenario

and Transportation Models |

|

APPENDIX G Proposed Temporary Storage and Sorting Area for C&D

Materials |

|

APPENDIX H Memo from Marine Fill Committee of CEDD |

|

APPENDIX I Control Procedures on Off-Site Disposal of C&D

Materials |

|

APPENDIX J Sample of CHIT Form |

|

APPENDIX K Protocol of Guidelines to Dump Truck Drivers |

合約編號HY/2012/07

屯門至赤鱲角連接路 -南面連接路高架道路段

泥車離開地盤環保要點

運泥車於離開地盤前,司機需注意事項:

1.

運泥車上的建築廢物已經篩選分類;

2.

離開地盤範圍前必須確保機動蓋掩或使用帆布完全蓋好車斗。否則需卸下物料並離開地盤;

3.

離開地盤範圍前檢查磅錶,切勿超越負荷;

4.

離開地盤範圍前必先沖洗車轆;

5.

已填好運載記紀錄票上的所有資料;及

6.

必須將運載記錄票上的第一聯交給駐地盤監工人士,方可離開。

本人明白上述環保要點,並會遵守。

簽名:

司機姓名:

公司名稱:

車牌:

日期:

|

APPENDIX L Sample of Daily Record Summary |

A sample of “Daily Record

Summary” to record daily disposal of construction & demolition (C&D)

materials from the Site

(1) Contract no. &

title:

HY/2012/07 - Tuen Mun Chek Lap Kok Link – Southern Connection Viaduct

Section

(2) Date of disposal:

_______________________________________________

(3) Designated disposal

ground(s): (a)

(b)

others

(4) Approved alternative

disposal

grounds:

|

CHIT / DDF Serial no. |

Vehicle registration mark |

Approx. vol. (e.g. Full/ Three Quarter/ Half/ One

Quarter |

C&D material type (e.g. inert or non

inert) |

Disposal ground |

Signature & Name of the GCL’s Designated person before

departure |

Departure time from site |

Signature & Name of the SO’s staff before departure or

other time as agreed between Engineer’s Representative and the

GCL1 |

Actual disposal ground |

Arrival time at disposal ground |

Remark |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ß----------------------------------------------------------------------------Part

1 2

---------------------------------------------------------------------------------------à |

ß-----------------Part

2 3 ---------------à | |||||||||

|

Submitted by: |

|

Name of GCL’s Designated Person |

|

Signature: |

|

|

|

Date: |

|

|

|

Received by: |

|

Name and Signature of the SOR |

|

Post: |

|

|

|

Date & Time |

|

|

Remark:

1) For the term contract, if

there are no full time site supervisory staff, the Supervising Officer’s

Representative should spot check and then sign as appropriate in accordance with

paragraph 25 of DEVB TC(W) 6/2010.

2) Part 1 - The GCL shall

complete Part 1 in duplicate and a copy should be kept by the Supervising

Officer’s Representative.

3) Part 2 - The GCL shall

complete Part 2 and submit the whole summary to the Supervising Officer’s

Representative within 1 working days after the records are posted at the EPD

website.

|

APPENDIX M Environmental Mitigation Implementation Schedule for Waste

Management |